Design of Digital Twin for Offshore Gas Condensate Field

December 2024

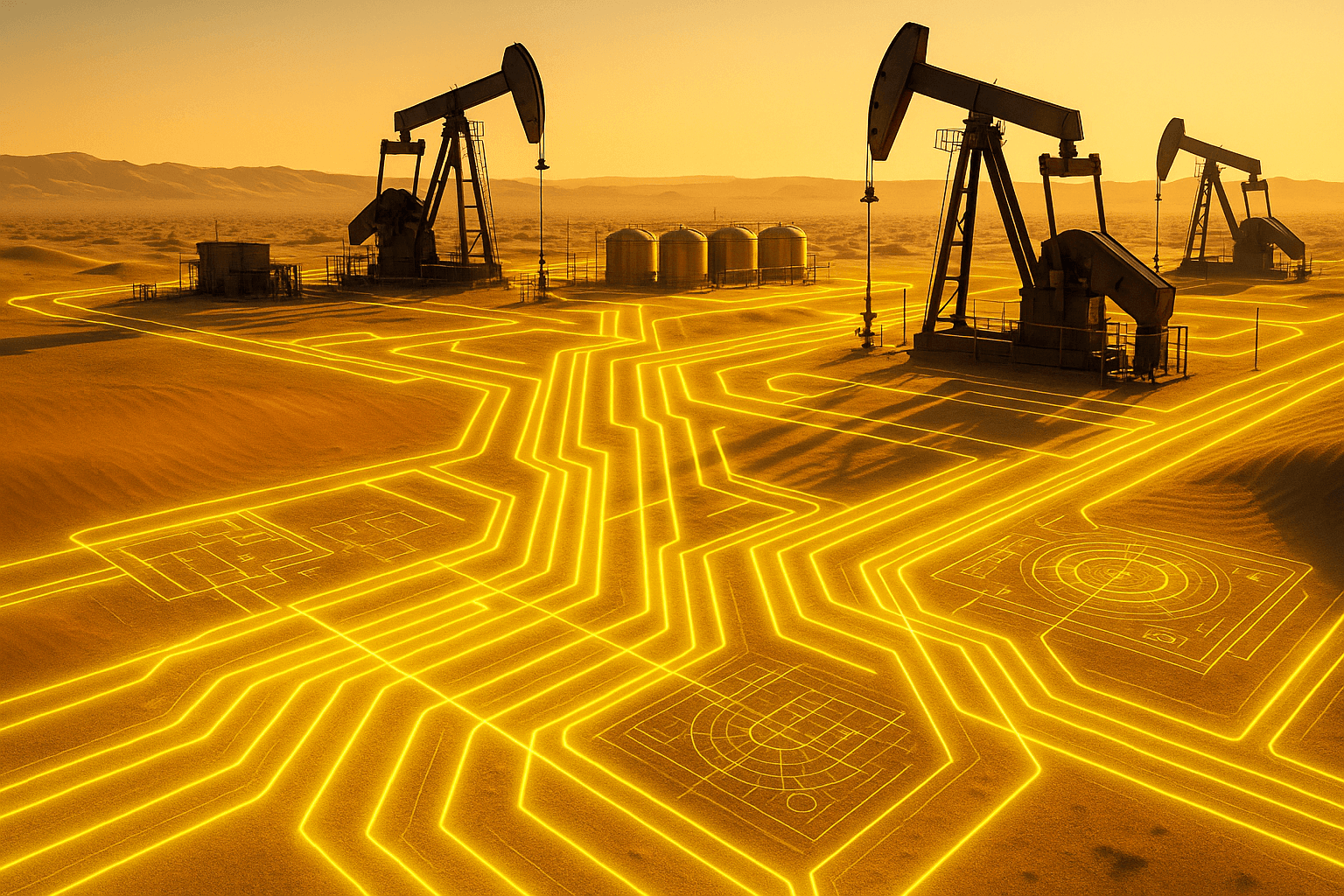

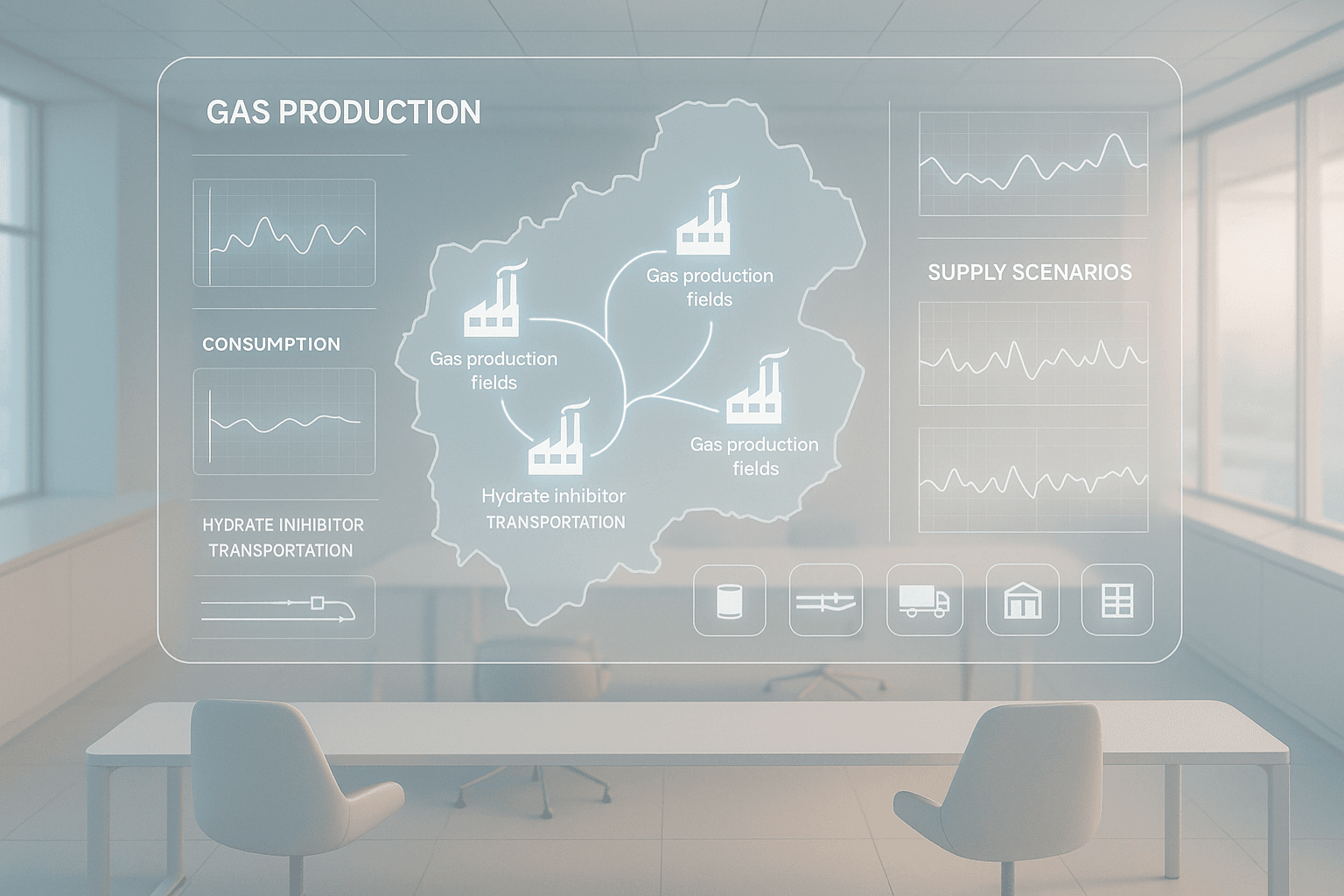

One of the major global gas producer has successfully partnered with us to deliver an advanced project for the design of a digital twin for an offshore gas condensate field with subsea production systems.

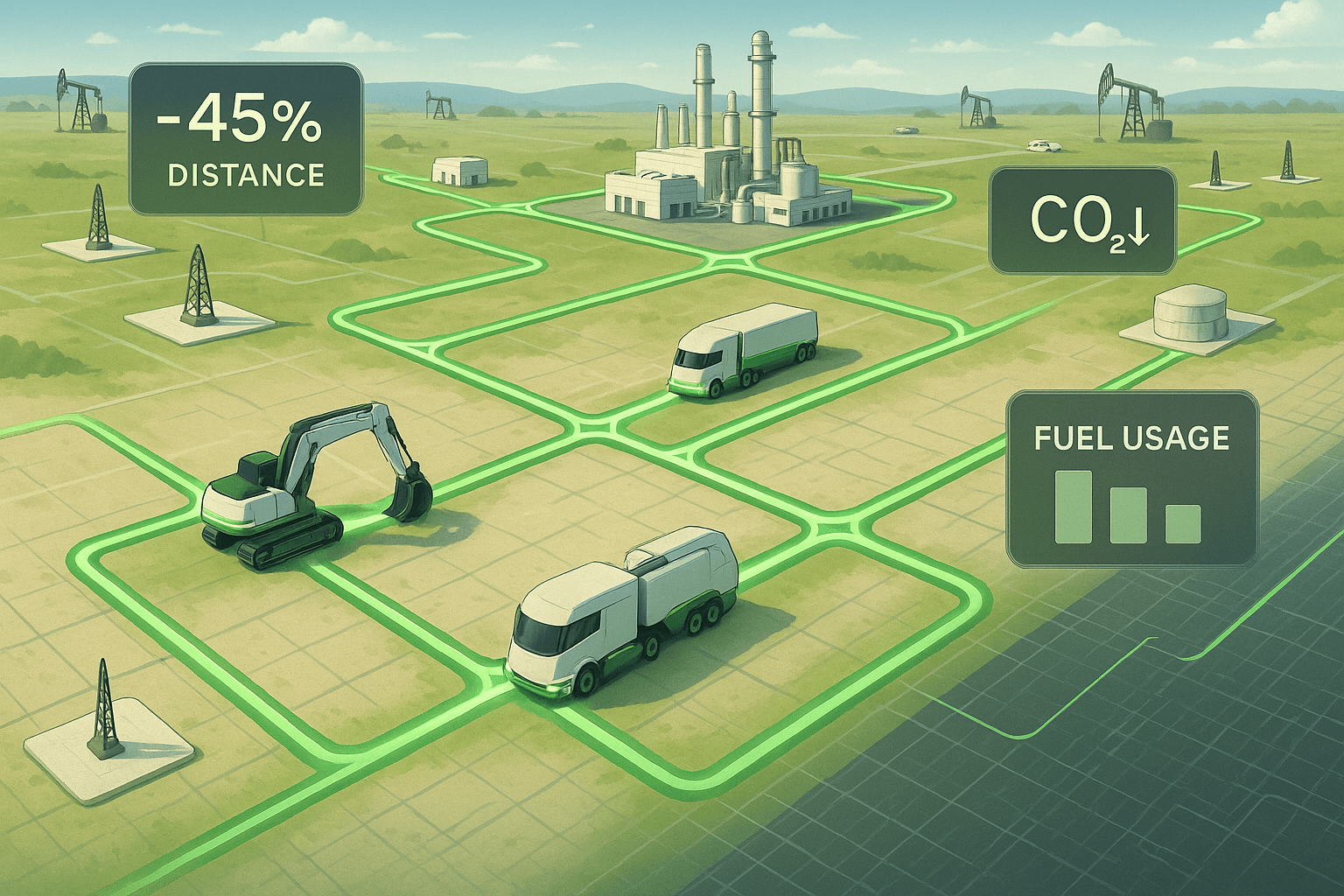

The project scope included a pre-project survey, analysis of best practices, elaboration of functional and technical requirements, engineering and conceptual design, selection of the most suitable software-hardware architecture, and a feasibility study for implementing a proactive management system for the offshore field.

The organizational scope covered the subsea production complex and the onshore gas processing plant with a condensate stabilizer. The produced fluids include dry gas, stable gas condensate and natural gas liquids.

Digital twin functionality

Key project objectives

Expected outcomes for the customer