How We Helped Optimize Shutdowns at Gas Production Sites

January 2026

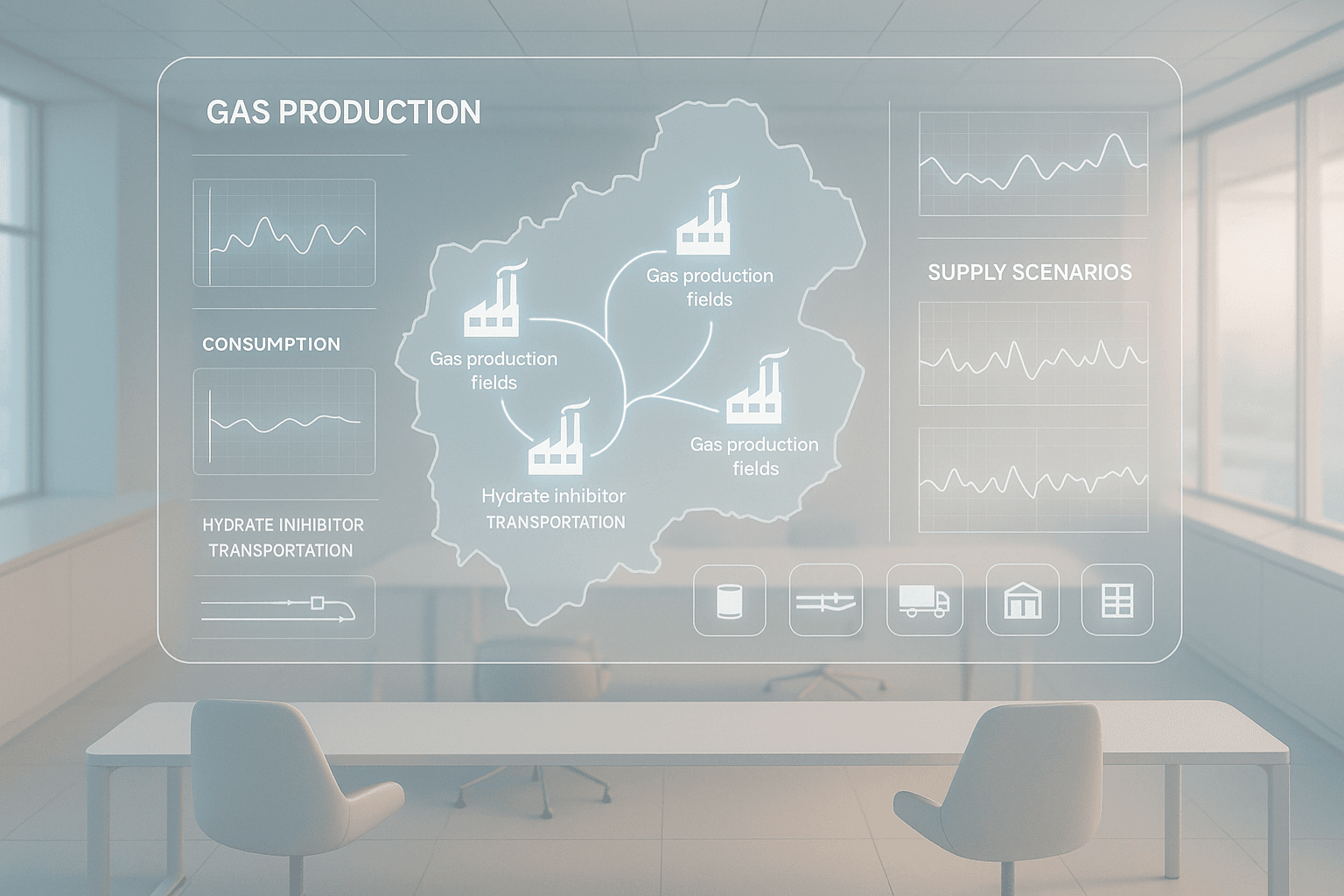

The end of 2025 was marked for our company by the successful completion of a pilot project to implement an nv.planning for a major gas production company. The project's key objective was to optimize the planning of annual field shutdowns and associated repair and maintenance work.

Our system enabled the identification of periods when equipment shutdown posed risks to fulfilling the monthly gas production plan. This made it possible to promptly adjust work schedules, thereby minimizing production losses.

Furthermore, we configured integration with an adjacent system that automatically optimizes well flow rates. The algorithm takes into account constraints related to gas composition and shutdown durations, helping to achieve business goals for production.

As a result, the client gained a unified digital environment. Within this space, it is now possible to plan activities involving the shutdown of an entire field or individual wells, as well as to instantly assess the impact of these plans on the achievement of the company's business objectives.

This project served as a clear example of how digital tools enhance the efficiency and manageability of critically important production processes.